Why Would We Spend 15 Hours Cutting a Unique Gemstone When Other Gem Cutters Spend Only 4 on a Standard Cut?

Because We’re Passionate About Selling Only the Finest Quality Designer Gems

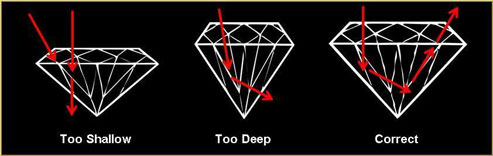

When it comes to gems, it’s all about the light, refraction and the cutting angles. To have a gem with a lot of brilliance, light has entered the Crown (top of the gem), bends (refraction), hits one side of the Pavilion (angled lower half), crosses over to the other side and returns up to the Crown. When the angles in the Pavilion are correct for that particular gem material, the gem will show its brilliance.

So, why wouldn’t gem cutters look for any opportunity to increase the number of facets as they work a stone? The answer, of course, is that it takes them more time. If you’re cutting just for the money, you’ll turn out as many stones as you can as quickly as possible. Faceting houses overseas employ gem cutters who may cut as many as 12 stones in a single day!

Can you imagine Rembrandt painting 12 masterpieces in a day? Neither can we. At Ashton Gems, our commitment is creating gemstones we’re exceptionally proud of.

It begins with carefully hand-selecting every rough stone we buy so there are no inclusions or fractures. Then we painstakingly cut the stone on the most highly-calibrated precision equipment available.

Finally, when it gets to the polishing stage, some people like to use Diamond (from 3,000 grit up to 100,000 grit). We prefer to use Cerium Oxide or Alumina when possible, but on some gems Diamond might be the only polish to work. We use Cerium or Alumina because it polishes quickly and leaves a smooth, brilliant finish.

Learn More. Visit our Gemstone Gallery

Gemstone Cutting Classes / Lessons in Tennessee Here

WE HAVE RELOCATED TO CLEVELAND, TENNESSEE

423-464-4287

“B” Still My Heart

14.7mm 10.4 Carat

Flawless pink Tourmaline

Contact us for price.